Types of Engines

This article is dedicated to the study of different types of

engines, as you know the engine is the power-producing device that generated

power is utilized in many different ways according to the application of a

particular machine.

Engines are energy conversing device. Engines are used to convert chemical energy of fuel into thermal energy and uses that generated energy to produce mechanical work. Mainly there are two types of engines:

1. External Combustion Engines

2. Internal Combustion Engines

Now, we discuss the first External Combustion Engines.

1. External

Combustion Engines

Simply, External Combustion Engines are the engines in which the combustion process takes place outside the cylinder body of the engine.

In external combustion engines, the products of combustion of air and fuel transfers the heat to a second fluid which is the working fluid of the cycle on which engine works.

Examples of External Combustion Engines:

In a steam engine or steam turbine plant, the heat of combustion is utilized to generate the steam which is used for the piston movement (reciprocating type engine) or a turbine (rotary type engine) for the useful work.

In a closed cycle gas turbine, the heat of combustion in an external furnace is transferred to gas, usually air which is working fluid of the cycle.

2. Internal

Combustion Engines (I.C. Engines)

In an internal combustion engine, the combustion of air and fuel takes place inside the cylinder and the generated power is directed to the motive force for the movement of the object.

And the exhaust gas generated by I.C. Engine is dumped into the atmosphere through the exhaust valves. So, there are plenty of aspects on which types of engines depend and those aspects are as follows:

(A) According to Type

of Ignition:

1) Spark Ignition

Engines:

Spark Ignition engine starts the combustion process in each cycle by the use of a spark plug. The spark plug is fitted on the head of the engine cylinder that gives a high-voltage electrical discharge between two electrodes which ignites the air-fuel mixture in the combustion chamber which is surrounding the plug.

In the early stages of engine development, before the invention of the electric spark plug, many forms of torch holes were used to initiate the combustion process from an external flame.

Generally, all the petrol

engines are spark ignition engines because the self-ignition temperature (S I

T) of petrol (gasoline) varies from 247°C to 280°C which is so high due to that

it requires an external ignition source provided by using the spark plug.

2)

Compression-Ignition Engines:

The combustion process in a Compression Ignition engine starts when the air-fuel mixture self-ignites due to a high-temperature rise in the combustion chamber which is caused by high compression.

Generally, Diesel engines are compression ignition engines (C I engines) because the self-ignition temperature of diesel is low that is 210°C which is easily achieved by the compression of air inside the combustion chamber. So in C.I. engines fuel injectors are provided in the place of a spark plug as in S I engines.

Don't Miss: What are the Types of Automobile Chassis?

(B) According to Use

of Fuel:

1) Petrol Engines:

Petrol engines are the engines in which petrol is used as

fuel for the combustion process and the whole working of the engines. Mainly

those engines are often called S.I. engines.

2) Diesel Engines:

In diesel engines, diesel is the main source for the fuel to

complete the combustion process and the whole working of the engines. These

engines are called as C. I. engines

3) Gas Engines:

In this type of engine, gas is used as the main fuel source

to perform the whole working of an engine. For example, LPG, CNG is used as a

fuel source for particular engines.

Don't Miss: Functions of Automobile Chassis Components

(C) According to

Engine Cycle

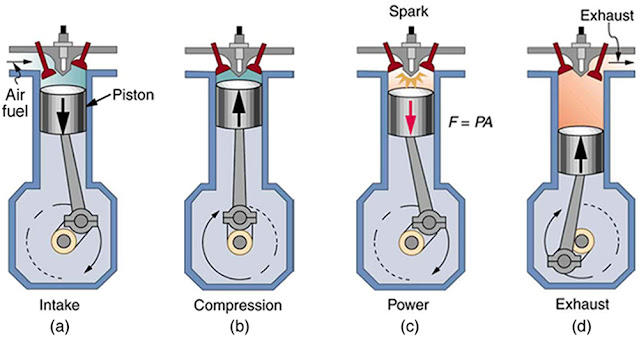

1) Four-stroke engine

cycle –

In the four-stroke engine cycle, there are four-piston

movements that take place over two engine revolutions for each cycle.

1. Suction: An intake or suction stroke that draws a

combustible mixture of fuel and air past the throttle and the intake valve into

the cylinder.

2. Compression: A compression stroke with the valves closed

that raises the temperature of the mixture. A spark that comes from the spark

plug ignites the mixture toward the end of the compression stroke.

3. Power: An expansion or power stroke resulting from the

combustion of the fuel-air mixture.

4. Exhaust: An exhaust stroke that pushes out the burned

gases past the exhaust valve.

2) Two-stroke engine

cycle –

As the name suggests, in a two-stroke engine cycle there are two-piston movements over one revolution for each cycle.

Two-stroke engines are

mechanically simpler than four-stroke engines, and those engines have a higher

specific power, the power to weight ratio. They can be used in either spark or

compression ignition cycles.

Don't Miss: Causes of Engine Overheating And Short Term Solutions For Engine Overheating

(D) According to

Cycle of Operation:

1) Otto Cycle:

The engine is working on the cycle designed by Otto. The

Otto cycle is also known as constant volume combustion or spark ignition cycle.

2) Diesel Cycle:

The engine is working on the cycle of operation designed by

Diesel. The diesel cycle is also known as constant pressure combustion or

compression ignition cycle.

3) Dual Cycle:

The engine works on both the cycle of operation that is Otto

cycle as well as Diesel cycle.

(E) According to

Number of Cylinders:

1) Single Cylinder

Engines:

The engine has a single-cylinder called single-cylinder

engines. This type of engine is generally used in two-wheelers such as

motorcycles, scooters, etc.

2) Double cylinder

Engines:

The engine has two cylinders called double cylinder engines.

Most of the two-wheelers have double cylinder engines such as Harley Davidson

motorcycles.

3) Multi-Cylinder

Engines:

In these engines, more than two cylinders are placed called

multi-cylinder engines. Such as four cylinders engines used in cars, six

cylinders engines used in trucks or buses.

Don't Miss: What is Automobile Chassis?

(F) According to arrangement and position of Cylinders:

1) Vertical Engines:

In these types of engines, the arrangement of cylinders and

pistons are vertical, these called vertical engines.

2) Horizontal

Engines:

As the name suggests that horizontal engines, the

arrangement of cylinders and pistons are in a horizontal manner that’s why it's

called horizontal engines.

3) Radial Engines:

In radial engines, the engines with pistons are positioned in a circular plane around the central crankshaft located. And the connecting rods of those pistons are connected to a master rod which is connected to the crankshaft.

A bunch of cylinders on a radial engine always has an odd number of cylinders and those are ranging from 3 to 13 or more as per the required application.

Radial engines are generally operating on a four-stroke cycle, every other cylinder fires and it has a power stroke as the crankshaft rotates, which helps to give the smooth operation of the engine.

Many of the medium and

large-size propeller-driven aircraft use radial engines. For large-sized

aircraft, two or more bunch of cylinders are getting mounted together and make

it as a single power-producing unit, one behind the other on a single crankshaft,

making one powerful, smooth engine. Very large ship engines exist with up to 54

cylinders; six bunches of 9 cylinders each.

4) In-Line Engines:

In these In-Line engines, pistons and cylinders are placed in position as a straight line, placed as one behind the other along the length of the crankshaft. Inline, engines can be consist of 2 to 11 cylinders or possibly more at one set.

In-line four-cylinder engines are very common and regular for automobiles and other applications. In-line six and eight cylinders are historically common for automobile engines such as for trucks and buses are other vehicles.

Because the structure of In-line engines is straight that’s why

these engines are sometimes called that straight engines (e.g., straight-six or

straight eight).

5) V-shaped Engines:

In V-shaped engines, there are two bunches of cylinders placed at an angle with each other along with a single crankshaft. The angle made in between those bunches of cylinders can be taken anywhere from 15° to 120°, with the angle of 60° to 90° being common for engines.

V-shaped engines

have even numbers of cylinders such as from 2 to 20 or more as per required

applications. V-6 engines and V-8 engines are common in most automobile

engines, with V-12 engines and V-16 engines (historic), can be found in some of

the luxury and high-performance vehicles and in some sports and muscle cars

too.

6) W shaped Engines:

W shaped engines are the same as V-shaped engines except that W shaped engines have three bunches of cylinders which are located on the same crankshaft.

These engines are not

so common and regular, but some of the engines have been developed for racing

and sports vehicles, both modern and historic. Usually 12 cylinders with the

making of about a 60° angle between each bunch.

7) Opposed Piston

Engines:

In this type of engine, there are two pistons in each of the cylinders with the combustion chamber is in the center between those two pistons.

Because of that single-combustion process takes place and that causes two power strokes at the same time, with each piston being pushed away from the center and delivering the power to the separate crankshaft which is placed at each end of the cylinder.

These engines have output is either on two rotating crankshafts or on

one crankshaft incorporating complex mechanical linkage as per the application.

8) Opposed Cylinder

Engines:

In opposed cylinder engines, there are two bunches of cylinders that are placed opposite each other on a single crankshaft (a V engine with a 180°V).

These are common on small aircraft and some automobiles

with an even number of cylinders from two to eight or more according to

requirement. These engines are often called flat engines (e.g., flat-four).

(G) According to

Valve arrangement:

According to the position and arrangement of the intake and

exhaust valves, whether the valves are located in the cylinder head or cylinder

block. Based on their arrangement, the

following are types of valve arrangements:

1) L Head Engines:

In L head engines, the intake and the exhaust valves are both located on the similar side of the piston and cylinder.

The valve

operating mechanism is located directly below the valves, and this required

only one camshaft that actuates both the intake and the exhaust valves. In this

arrangement, the combustion chamber and cylinder make inverted L shape

so-called L head.

2) I Head Engines:

In I head engines, the intake and the exhaust valves are both mounted in a cylinder head direct exactly as above the cylinder.

This type of arrangement requires some needful components such as a tappet, pushrod, and a rocker arm which is placed on the above of the cylinder to reverse the direction of valve movement.

Although this configuration is the most popular

for the current generation of gasoline and diesel engines, and it is rapidly

being superseded by the overhead camshaft.

3) F Head Engines:

In F head engines, both the intake and exhaust valves are placed in different positions. The intake valves are located in the cylinder head, while the exhaust valves are located in the engine block.

The intake

valves in the head are operated by the camshaft through tappets, pushrods, and

rocker arms. On the other hand, the exhaust valves are operated directly by

tappets on the camshaft.

4) T Head Engines:

In T head engines, the intake and the exhaust valves are located on the opposite sides of the cylinder in the engine block, and each of the valves require their own camshaft to operate.

Some of the historic or old

engines with having valves in the block had the placement of intake valve on

one side of the cylinder and the exhaust valve on the other side of the

cylinder. These were called T Head engines.

Don't Miss: Chassis Layout of Automobile

(H) According to Type

of cooling

Based on the type of cooling of an engine, there are the

following types for I.C. engines:

1) Air-Cooled

Engines:

In this type of engine, the air is used for the cooling

purpose of engines. For the cooling, metal fins are provided that increases

radiating surface for heat dissipations and enhance the cooling of engines.

Generally, this type of engine is used in motorcycles, scooters, etc.

2) Water Cooled

Engines:

In these engines, water is used for the cooling purpose of

an engine. These engines have radiators for the cooling of hot water from the

engines. Water-cooled engines are mostly used in cars, buses, and other heavy

vehicles. Some coolants are also added to cooling water for the better cooling

of engines.

(I) According to

method of governance:

Most of the small engines have a governor to regulate and maintain the engine speed as constantly as possible according to changing the load. Some of the engines also have an adjustable throttle by which the operator or the machine itself can alter the engine speed.

Generally, the

nominal “throttle control” does not directly control the opening of the

carburetor throttle, but rather increases or decreases the spring tension which

is placed on the governor, which helps to regulate the engine speed higher or

lower.

In this type of engine, the entry of the fuel is controlled

by using the governor. And it controls the speed of the engine while cutting

off the ignition and fuel supply of an engine at a very high speed.

1) Hit and Miss governed engines

2) Qualitative governed engines

3) Quantitatively governed engines

Don't Miss: Types of Renewable Energy Resources

(J) According to

speed of engines:

1) Low-Speed Engines:

As the name suggests that the engines which are designed for low-speed requirements are called that low-speed engines.

Also known as

slow-speed, or traditionally oil engines, the largest diesel engines are mainly

used to power the marine ships, even though there are a few stationary power

generation units as well.

2) Medium Speed

Engines:

Medium-speed engines are the engines that are working on medium speed requirements. Medium-speed engines are mostly used for large-sized electrical generators, ship propulsion, and mechanical drive applications such as large-sized air compressors or pumps.

Medium-speed engines operate on either

diesel fuel or heavy fuel oil by the direct injection in the same way as done

in low-speed engines

3) High-Speed

Engines:

Engines that are working at high speeds are called that high-speed engines. Mostly, high-speed (approximately 1,000 rpm and greater) engines are used to power heavy-duty trucks (lorries), buses, tractors, cars, yachts, compressors, pumps, and small electrical generators.

As of 2008, most

of the high-speed engines have direct injection system. Many of the modern

engines, particularly in on-highway applications, have common rail direct

injection, which is cleaner burning.

Don't Miss: Classification of Automobile and How Automobiles are Classified?

(K) According to fuel

injections method:

Based on the fuel injection method, there are the following

types of engines:

1) Indirect Injection

In an indirect injection system, the fuel discharge into a

chamber that is placed off to the main combustion chamber called a

pre-combustion chamber, where combustion begins and then it spreads into the

main combustion chamber that is assisted by the turbulence created in the

chamber. This system gives a smoother, quieter running engine.

2) Direct Injection

In a direct injection

system, the diesel engines having injectors mounted on the top of the

combustion chamber. Those injectors are activated by using one of two methods

and that is - hydraulic pressure from the fuel pump or an electronic signal

from an engine controller.

Hydraulic pressure-activated injectors can produce more engine noise. And fuel consumption is about 15–20% lower than indirect injection.

The extra noise is generally not a problem for industrial uses of

the engine, but for automotive usage, it makes trouble, and buyers have to

decide whether or not increases the fuel efficiency that would compensate for

the extra noise.

Electronic control of the fuel injection system, it is

transformed the direct injection engine by producing much greater control over

the combustion.

3) Unit Direct

Injection

In the unit direct injection system, the injector and the pump are combined into one unit positioned over each cylinder and it is controlled by the camshaft.

Unit direct injection also injects the fuel

directly into the cylinder of the engine. And every cylinder of the engine has

its own unit by avoiding the high-pressure fuel lines, that achieving a more

consistent injection.

4) Common Rail Direct

Injection (CRDi)

In common rail direct injection, the common rail is a tube

that supplies each computer-controlled injector that contains a

precision-machined nozzle and a plunger which is operated by a solenoid or

piezoelectric actuator.

Don't Miss: What Is Automobile?

(L) According to

applications:

1) Automobile

engines:

Automobile engines are the engines used in automobile

industries such as cars, buses, trucks, and other types of vehicles.

2) Locomotive

engines:

Engines that are used in trains are locomotive.

3) Marine engines:

Engines are used in the ships and boats for the propulsion

of ships and boats are generally marine engines.

4) Stationary

engines:

Stationary engines are the engines used to run the types of

equipment that are stationary such as pumps, generators, and other industrial

types of machinery.

5) Aircraft engines:

Engines that are used for the aircraft are coming in the

category of aircraft engines. Mostly gas turbine and radial engines are used in

aircraft.

Don't Miss: Continuously Variable Transmission (CVT) Transmission System

* Smart Engines:

Smart engines are engines that are controlled with a

computer control system that regulates the operating characteristics such as

air-fuel ratio, ignition timing, valve timing, exhaust control, intake tuning,

and so on. And computer inputs are coming from electronic, mechanical, thermal,

and chemical sensors located throughout the engines.

In some vehicles, computers are even programmed to adjust the engine operation for the things like valve wear and combustion chamber, deposit buildup as the engine ages gets older.

In most automobiles, the same

computers are used to make the vehicles smarter by controlling the steering,

brakes, exhaust system, suspension, seats, anti-theft systems,

sound-entertainment systems, shifting, doors, repair analysis, navigation,

noise suppression, environment, comfort, etc.

On some of the systems, the engine speed is to be adjusted

at any instant when the transmission shifts gears, resulting in a smoother

shifting process. At least one of the automobile models even adjusts this

process for the transmission fluid temperature to assure that smooth gear

shifting at a cold startup.

This is all about the different types of engine, if you find anything missing or incorrect then don’t forget to mention in the comment box. And if you enjoy this article then hit the like and share with all.

Comments

Post a Comment

If you have any doubts and queries please let me know