Steering System

Automobile is fragmentary without the steering system as it gives the directional stability. Steering system enables that the driver to easily maneuver the vehicle according to the path.

It’s not mean that automotive, when developed included steering mechanism. So, here one question arise that how the steering wheel which we see on today’s car was invented?

Image source: Here360

The automotive freaks, during those days got the idea of steer the vehicle from boats which used tilter that helped them to turn left or right. The idea was implemented on automobiles too. But didn’t last longer as it required that it takes more effort and the steering ability was almost poor.

The ultimate discovery of the steering wheel was seen in Pan hard model which

was tested in the Paris – Roven race. This innovation was then seen in every

car model that followed and as such the round steering wheel become important

and compulsory element of the car.

The

steering system is however not as easy as it seems, where you simply turns the

steering wheel that turns the road wheels. It is composed of complex mechanisms,

linkages, joints and gears that actually make the wheel to turn.

Now,

here one question strikes in our mind that is How the steering system actually works? As we know that the basic function of steering

system is to turn the wheel in the desired direction. Now here, it is

interesting to note that when the vehicle is turned, the front wheel do not

point in the same direction. Let’s see how this possible.

For

the proper steering system, each of the wheels must follow different turning

circle and when a perpendicular is drawn from the center of the each wheel; all

the perpendiculars will meet at one single point, which is known as

instantaneous center.

But

then the question is still goes unanswered, that how the wheel actually turns?

Looking closely to the figure, here we can see that the complex mechanism of the steering system which makes the car wheels to turn.

The system works on four

bar chain mechanism where four links are flexibly connected with each other and

imparting the motion, to one of the link will make to move other links accordingly.

The

steering wheel is directly connected to steering gear, which have the main

function to convert the rotary motion of steering wheel into oscillatory motion

of the pitman arm. This motion is transferred to the tie rod through the drag

line, which is able to move tie rod left or right depends on the steering wheel

input. The ends of tie rod are connected to the pivots that actually turn the wheels.

The

mechanism of steering is remains same in all the steering system, but the

difference can be seen in the types of gearing arrangement in steering gearbox.

The types of steering gear mechanism used in automobile power steering listed

below:

Types of Steering gear mechanism:

1.

Rack and Pinion steering gear

2.

Worm and Sector steering gear

3.

Worm and Roller steering gear

4.

Cam and lever steering gear

5.

Worm and Nut steering gear or Re-circulating ball type steering gear

Most

common type includes Rack and Pinion and Re-circulating ball (Worm and Nut)

type arrangement

1. Rack and Pinion Steering gear

The System consists of pinion attached to the steering shaft, which meshes with the flat rack on the drag line. Pinion transmits left or right motion to the rack which causes the tie rods that connected to the pivots to move the road wheels consequently.

This mechanism is usually adopted universally in all the cars which are available in the market today with some major improvements.

Earlier, steering system was robust, though it was quite heavy and difficult to use. The need of more flexible and smooth system was desired and as such some of the vital experiments in 1920 gave birth to power steering system.

The entire

credit goes to Francis W. Davis who was an engineer in automotive industry.

With Francis W. Davis efforts, power steering system started to be used

commercially in all the cars.

2. Worm and Sector steering gear

In this type of steering mechanism, worm is to be connected at the end of the steering shaft and the sector is mounted on a sector shaft.

The sector looks similar

like a ball and worm looks similar like a gear. The teeth of the worm meshes

with the teeth of the sector. To provide a free play, worm is to be mounted on

the bearing. It is also known as ‘Pitman arm shaft’.

3. Worm and Roller steering gear

Worm and Roller similar to the worm and sector type of steering gear system. In this steering gear mechanism, a toothed roller is mounted on a roller shaft and worm gear is mounted on a steering shaft.

Gear tooth of a worm gear meshes with that

of the roller and motion is transmitted. The roller is mounted on ball bearing.

This mechanism has low friction as compared to worm and sector steering gear

mechanism and is widely used in American passenger cars.

4. Cam and lever steering gear

Cam and Lever is similar to worm and sector gear mechanism. In this steering gear, the worm is replaced with a cam and sector is replaced with a lever.

Cam is

engaged by using the bearing and lever, carries two studs that are mounted on

bearing. As the driver starts to turn the steering wheel, studs move up and

down on the cam so lever and Pitman arm shaft gets rotated.

5. Worm and Nut steering gear or

Re-circulating ball type steering gear

In

worm and nut steering gear, a nut is meshed with the worm and screws up and

down relative to the movement of the worm. This mechanism is also called as

re-circulating ball type mechanism. Nut is used with the ball that helps to

reduce the friction and power loss.

Without

increasing further impatience let us look the power steering system implemented

on the normal rack and pinion steering system.

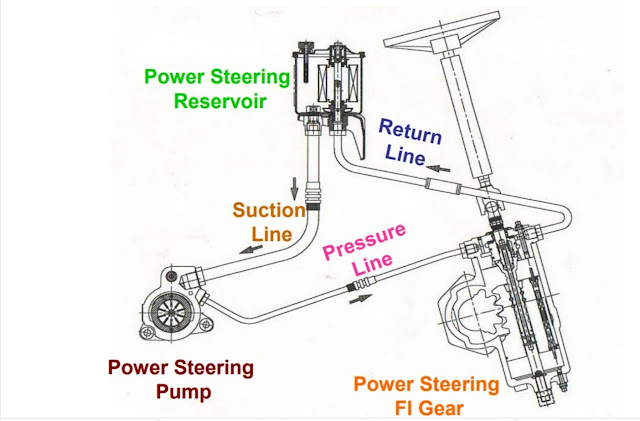

Power steering refers to the use of hydraulic power assisting the steering motion. When coupled with any of the steering system, the power steering makes the use of pump which forces the fluid under pressure, to help the steering gearbox, to overcome the friction and easily turn the gears and impart the movement to the road wheels.

Power steering makes the steering wheel to turn easily and also a

small effort, on steering wheel gives sharp turning to the road wheels.

Power steering got new dimension with use of electric motor and sensors that do not use the engine power but run separately using the battery. The sensors are used for sensing the torque and motion which is applied to the steering wheel.

On

the basis of that, the control unit, powers the motor to assist in the steering

mechanism. At this junction, it is also important to know the term steering

ratio which helps to determine the steering ability of particular steering

system. Steering ratio can be defined as the ratio of number of degrees that the

steering wheel turns to the number of degrees of the get wheel turn.

Steering

ratio for the car varying from 12:1 to 20:1. For example, if we want to turn

the wheels to 20 degree by one complete revolution of steering wheel, the ratio

will be 360:20 or 18:1.

A

higher steering ratio required more turns of steering wheel but effort required

will be less.

Power Steering

Increasing the use of large section low-pressure balloon tyres has aggravated the steering problem due to greater contact area between the tyre and ground.

Driver required a greater force to be excelled on the steering wheel to steering the heavy vehicle or heavily loaded commercial vehicle, especially when the vehicle has to take a sharp turn.

Power steering makes it easier to turn sharp corners. It is fitted not only in commercial vehicles but also to heavy and medium weight cars. It is usually arranged to be operative when the efforts on the steering wheel exceeds a pre-determined value.

When this effort is excluded, a valve as directed the working fluid to the appropriate side of the power cylinder and this results in the steered wheel being turned in the desired direction. The working fluid is high quality lubricating oil having a viscosity rating equivalent to ASE low for normal conditions.

The actual amount of

assistance given depends upon the resistance offered to the movement of the

road wheels.

There

are usually two general types of power steering system:

1.

Integral Power Steering: in this system the power operating assembly is part of

the steering gear

2.

Linkage Power Steering: in which the power operating assembly is part of the

linkage

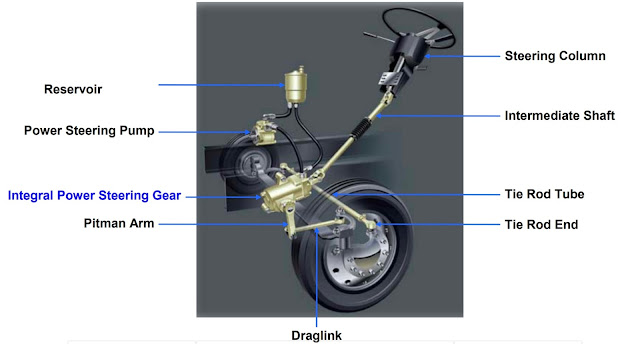

Integral Power Steering

The integral power steering is designed to receive power assistance only when the effort at the steering wheel rim exceeds two pounds and is up to five pounds.

It consist of a worm and ball bearing nut steering gear with a hydraulic rack piston, concentric with the worm shaft which can aid in moving the nut in either direction by means of hydraulic pressure. A reaction contract valve is linked to the worm shaft thrust bearing through the link and actuator lever.

Any moment of the thrust bearing causes

the control valve to move which opens and closes oil passage between the valve

body and the housing of the gear and pinion assembly. As we know the working of

the integral steering while taking the right turn, when the vehicle is going

straight ahead the oil flows from the pump through the open centre of the

valves and back to the reservoir.

New Technologies and Innovations in

Steering System

Many new innovations done in steering system are available today that gives best possible directional stability to the cars with the extreme comfort levels. Some of the improvement includes that four wheel steering which assists in steering all four wheels of the cars. This will help in maneuvering the car at high speeds.

Some of the cars today also include a system known as speed sensitive steering, which using a concept that during a high speed steering requirements are less as such the power assistance is reduced. It is increased during the low speed as more steering effort is required.

Future developments in the

steering system are being done by the experts and have come up with an idea of

steer by wire mechanism in which the steering will be achieved completely using

electronics. The ultimate aim of this system is to eliminate the complex system

of linkages and joints giving more space for engine and interior designing

aspects.

Car Steering Wheel,

Image of Rack and pinion steering system,

Rack and pinion steering system,

Types of steering system,

Steering system ppt,

Steering system PDF,

Steering system parts,

Steering system diagram,

Function of steering system,

Four-wheel steering system,

Comments

Post a Comment

If you have any doubts and queries please let me know